How Are Vanilla Beans Harvested?

Cultivating high-quality vanilla beans is a demanding and time-consuming task. Due to the intense labor involved, vanilla ranks as the second most expensive spice in the world, surpassed only by saffron. Additionally, unfavorable weather can cause worldwide shortages, sometimes pushing vanilla prices even higher than saffron's.

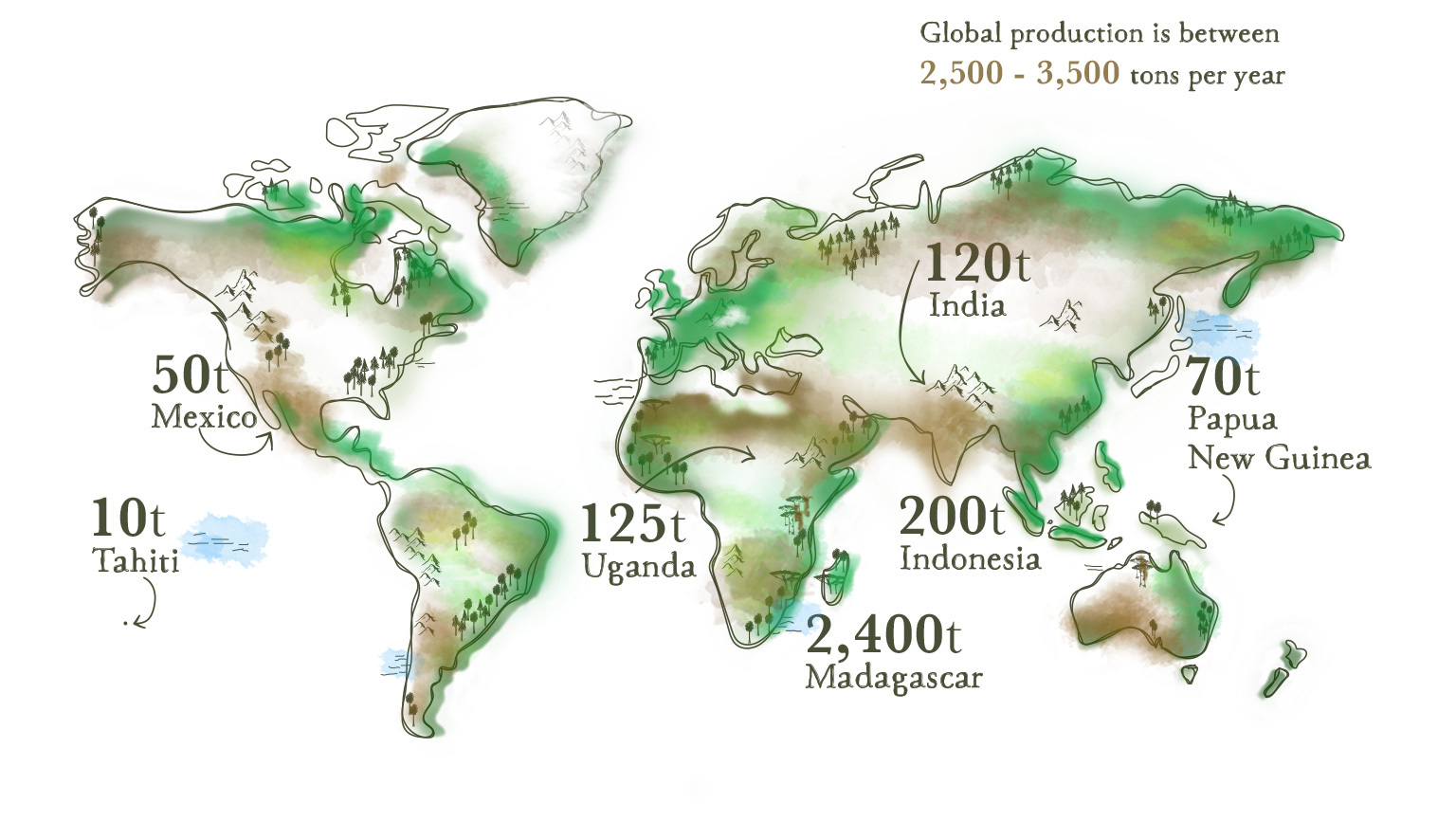

Vanilla beans are cultivated in tropical areas across the globe, where consistently warm temperatures and adequate rainfall provide the ideal soil and climate for healthy development. Interestingly, the beans are green—not brown—at the time they are harvested.

Vanilla beans thrive within the "Bean Belt"—a warm climate zone located 20 degrees north and south of the equator. This region is also home to coffee beans, cocoa beans, and several other types of beans. However, vanilla beans are the most delicate during the growing process, as they originate from a fragile flower.

Similar to many other orchids, the Vanilla Planifolia—also known as the vanilla bean orchid—is an epiphyte that grows on a host tree. It’s a fast-growing vine that winds its way up and around the tree without taking any nutrients from it. The vanilla orchid may take up to three years before it begins to produce the fragile blossom that eventually forms the vanilla bean. Once pollinated, the pods need another 9 to 10 months to fully mature before they are ready for harvest.

Every vanilla bean orchid must be pollinated by hand for a vanilla bean to develop, largely due to the probable extinction of the native vanilla bean bee. Successful pollination usually needs to take place within six hours of the orchid’s bloom, or it won’t take. If timed correctly, a single vanilla bean will begin to grow and reach maturity about 9 months later.

Here is a 60 second video that shows how each orchid is pollinated.

Of course, pollination is only the beginning. Afterward, the orchid must stay in optimal conditions—proper climate, shade, and humidity—to produce a strong, healthy bean.

When ready for harvest, healthy vanilla beans are green and usually measure between 4 to 9 inches in length, depending on the variety. Here's a photo of healthy vanilla beans.

Once the beans are fully developed, they are clipped from the vines and the harvesting process begins. Proper harvesting involves several important steps, which we’ll outline below.

Phases of Vanilla Harvesting

There are 6 key phases in the vanilla harvesting process. Each step requires careful attention to temperature and moisture levels to ensure success.

1. Harvesting

Beans are gently removed from the stem using a sharp blade. At this point, they are still green and lack any distinct aroma.

2. Killing / Blanching

To stop further growth, the beans are soaked in hot water. This process not only halts vegetative development but also eliminates potential pathogens on the surface.

3. Sweating

The beans are placed in the heat during the day and wrapped in blankets at night. This “sweating” process helps release the vanilla's natural flavor and fragrance, which begin to emerge during this stage.

4. Drying

Much like sweating, drying is a nuanced phase requiring both experience and scientific precision. The beans are spread out in the sun during the day and stored indoors at night until their moisture content falls to between 18% and 35%. (Grade B vanilla beans are dried longer and retain about 20% moisture, while Grade A beans are dried less and hold around 30% moisture.)

(Vanilla beans drying in the sun)

5. Grading

After drying, the vanilla beans are sorted and classified according to their quality, shape, and moisture level into categories like 'Grade A', 'Grade B', 'Grade C', 'Gourmet', 'Extract Grade' or 'Black'. Grade A and Grade B distinctions are based on measurable moisture content, while terms like 'Gourmet' or 'Black' or 'Extract Grade' are more subjective and vary by source or region.

6. Transportation

Once sorted, the beans are organized by grade, bundled, and typically vacuum-sealed. Vacuum sealing is essential because it locks in the bean's current moisture level—preventing any loss or gain—ensuring the bean maintains its designated grade from farm to customer.

From the initial planting to final packaging, the entire vanilla process can take up to four years, making it one of the most complex agricultural products in the world.

When we get vanilla beans, each bean is carefully examined by hand to verify it meets our quality standards. After inspection, we vacuum-seal the beans in pouches, grouped by weight or quantity, and ship them in sealed, protective envelopes or boxes.

When our customers receive their beans, we recommend storing them in their vac-sealed packaging in a cool, dry, and dark environment until use. While the shelf life can extend up to a year, we advise using them promptly. For maximum preservation and to prevent mold, storing the beans submerged in alcohol (Mother Jar) is the safest option.